MOQ Meaning

What are MOQs? MOQ is an acronym that stands for “minimum order quantity”. It means the minimum quantity of items a manufacturer will accept for a production order.

For example, if a clothing manufacturer offers an MOQ of 50 pieces per style, then you would need to order at least 50 pieces of a particular style to meet a supplier’s MOQ requirements for a single production run. Nearly all suppliers set an MOQ of some kind. Each supplier’s minimum order quantity will vary widely based on what type of factory they are, what they’re making and where they are located.

MOQs Depend on Manufacturer

Each manufacturer will define MOQ differently. Some will base their MOQ on total order size, such as a minimum of 1000 pieces of an item, regardless of color or size. Others may set their minimum based on style, color, size, or any other variable. The specific rules depend on the workflow of the manufacturer and what makes the most sense for them. At the end of the day, MOQ is all about maximizing efficiency. That will change depending on the particular manufacturer.

MOQs Depend on Product

MOQs will also depend on the type of product being manufactured. Some products are far more complex to produce than others. But it’s HOW a product is made that makes the bigger difference. Something handmade, for example, might be able to be made in quite a small quantity. Something made on a specialized machine, meanwhile, might require an MOQ in the many 1000s just to be worth programming the machine and running it.

For example, it’s no big deal to print off a single copy of a document on an inkjet printer, right? Well now imagine that you’re using letterpress to do the same document. You’d need to make a plate, ink the plate, and use a press to create it. That’s a tremendously different process for roughly the same product. In other words, the process used has a dramatic effect on the MOQs.

At Prototype, we offer lower MOQs than most clothing manufacturers in our industry. Even for us, however, the MOQ ultimately depends on the type of clothing being made and the techniques involved in making it.

How many units is considered a “Low MOQ” or “High MOQ”?

Whether a certain quantity of items is considered “low” or “high” MOQ depends entirely on the manufacturer. A manufacturer working alone might consider 100 units to be a high quantity, but a proper factory may not even consider an order that low.

There is no “standard” in any industry for determining MOQs. However to give you a helpful start… VERY generally speaking, here are some basic guidelines that we often encounter when we’re sourcing production for our own partnerships:

- A “Very Low MOQ” manufacturer would be any production (generally something smaller than a factory) that accepts fewer than 250 pieces style.

- A “Low MOQ” manufacturer would be a smaller factory that would reluctantly accept perhaps as low as 250 pieces, but starts to perk up when you’re talking upwards of 500 units.

- A “Standard MOQ” manufacturer is a mid-sized factory that is looking for 1000-2500 MOQ

- A “High MOQ” manufacturer might start at around 2000-5000 units as an opening order, but would typically be looking to secure order in the 10’s of thousands of units.

So, clearly, when you’re looking for manufacturers it makes sense that some of the bigger factories you might be considering may not be feasible if you’re only looking to order 50 pieces. If you are ordering at a small scale, you should be focused on finding smaller manufacturers who will appreciate your business.

MOQs and Prices

What impact do MOQs have on pricing?

MOQ relates to order quantity and quantity usually relates to pricing. So how big an impact does MOQ usually have on pricing? With custom manufacturing, it will usually have a VERY big impact on price. In general, high quantities are available at a lower price per unit. Low quantities are available at a higher cost per unit. The difference can be huge. If a fashion label is looking for a low MOQ manufacturer, then they shouldn’t expect to receive high volume pricing.

However, if you have an online store and you’re looking for private label, white label or wholesale suppliers then your MOQ may not be such a big issue. Items manufactured in advance and not made to order will be less sensitive in terms of MOQ.

Why do factories have such high MOQs?

Simple. Apparel manufacturers have high MOQs for efficiency. The communication and setup of a new garment manufacturing order is a lot of work! To start with, there must be a detailed review of the tech packs. The tech pack alone could be 10-20 pages or more.

Then, there’s all the back and forth discussion about pricing. Figuring out which fabrics will be used and whether they are available. Sourcing zippers, buttons, snaps, rivets, etc. And all the internal details such as scheduling the job, the staffing and all the various overhead that goes into the job. In addition to the garment production itself, there’s also the possibility that the designer still needs to work through all the prototyping and sampling processes. That alone can take a tremendous amount of time.

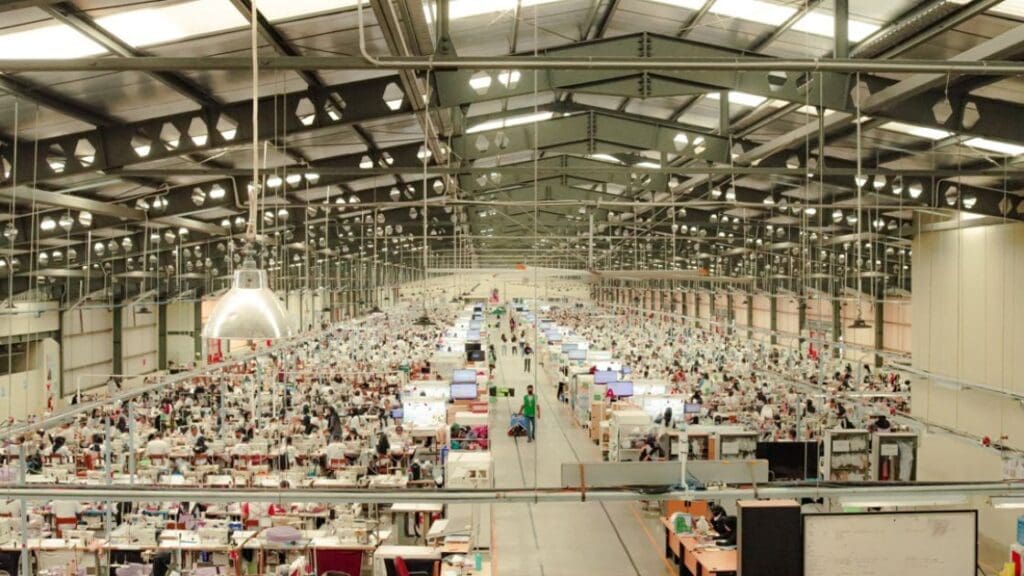

Big Garment Factory MOQs

Big apparel manufacturer requires a high enough MOQ to be able to cover their overhead and profit through the garment production itself. They will not typically have budgeted for a great deal of product development work. That helps keep their prices down. Keep in mind that there are a LOT of positions within the company aside from the sewing factory staff. Here are just a few that have to be considered by the business owners:

Common Factory Expenses

- Accounting

- Human Resources

- Sales & Marketing

- Janitorial

- Quality Control

- Delivery & Warehouse

- Supervisors & Floor Managers

- Parking/security/facilities/etc.

Wow, lots of people to consider! Not to mention the electric power, water, supplies, internet… even coffee. Lots of various fixed overhead costs!

Labor and fabric costs are just the beginning! Every expense of the company, plus profit, must be covered by the garment manufacturing prices.

A Big Factory May Be a Poor Fit for Startups

The garment industry faces heavy competition and tiny margins. So you can easily imagine that it could take quite a few pieces in a single order to be able to cover the costs of operating the whole company. Many start-up fashion designers don’t make that connection at first. They’ll often come in asking for both the minimum size order and the best price. Then they’ll also expect the apparel manufacturer to produce free prototypes and samples.

If you add the cost of all the staffing and the overhead, plus add the cost of developing and sampling the product, the costs add up quickly. It would require a huge order volume to cover the costs of all these services. High MOQs, then, is a simple way of filtering out the smaller clients who may need more services than they are able to pay for.

This also explains why many designers and smaller labels are often ignored by these larger factories. It seems like poor customer service, but in reality, there’s a very real possibility that they may just be trying to scare you off. For most smaller clients, this direct-to-factory approach to developing a new fashion line is just not going to be feasible.

To expect a realistic bid from a manufacturer, the product development process should be complete and you should have your tech pack finalized, or very nearly. A fashion label should be ready to meet the MOQ meaning they should be able to move forward with an order if they receive a fair quote from an apparel manufacturer. If you’re not ready, then you may end up burning a bridge you might later wish you hadn’t. Here’s a better way to approach it…

Do This First: Fashion Product Development

The best approach to developing a new fashion line is through a fashion product development company. While not strictly an “apparel manufacturer”, a product development company will help move you through the initial steps to prepare your fashion line for manufacturing. They may be able to assist with either small-scale garment manufacturing. Or they may at least help with sourcing apparel manufacturers who accept small MOQs. What’s an MOQ typically for a product development agency? That depends too, but typically you’ll find MOQs to be far smaller than going straight to a factory.

The Fashion Product Developer Difference

Why the smaller MOQ? Because the development process is separate from manufacturing. The development costs are paid separately. Which eliminates the need for high MOQs. A fashion product development company will charge for all the time and materials involved in designing and prototyping the clothing products. The costs of prototyping and sampling fashion designs will vary widely depending on where you have it done. There’s no standard pricing for fashion product development. It’s the same as with any design field: you choose the team you’d like to work with based on their portfolio and references and go with it.

Price shopping and comparing services is something you’re going to want to do first, before you sign on the dotted line. Once you’ve made the decision to work with someone, you could lose a lot of time, progress and money if you decide to switch to another provider. Like design, it’s a creative process, so there will be no guarantees. If things aren’t working out as you’d hoped, you’ll be free to select another company that you’d like to work with.

Once the fashion product development process is complete, you’re ready for production. If the company offers apparel manufacturing for the type of garment you’re producing, you’re in luck! Often, however, the product development company won’t offer manufacturing. For those items, they may refer you to work with another company. Or you may need to source your own apparel manufacturer. That part can be a challenge! But if you develop your own fashion line correctly, you’ll be able to provide the garment factory with exactly what they need to give you an accurate quote.

How to Get a Quote From a Manufacturer

Let’s be honest here. If you were a real estate agent, the last thing in the world you want to be doing is taking working weekends to show houses. Especially to people who aren’t actually looking to buy, right? The dreaded tire kickers! Asking for quotes from manufacturers whose minimums you know you can’t meet is much the same thing. Providing an accurate quote can sometimes take hours. And of course it’s unfair to ask someone to unknowingly work for free. It’s bad manners. But people do it. A LOT. The more unfair advantage is taken, the less likely an apparel manufacturer is to provide you with a realistic quote when you really need one.

When you’re out trying to price out your collection, you’re going to run into a lot of factories that are reluctant to quote anything for you. Now you understand why that is. If you really need a quote, be honest and respectful of their time. Build some trust. Give them the impression that you’ll be a great client.

Remember always that your relationship with your manufacturer is just that– a relationship. Take good care of your business relationships and they’ll take care of you!

Richard Gregory, Prototype Founder // CEO