The Question Behind Every Collection

Every fashion brand, at some point in its journey, faces the same fundamental question: how do I get color onto fabric? It sounds simple enough. But spend ten minutes researching your options and you’ll discover a sprawling landscape of techniques, each with its own requirements, limitations, price points, and ideal use cases. Sublimation, screen printing, DTG, reactive dyes, batik, piece dyeing, garment dyeing… the terminology alone can make your head spin.

Here’s the thing: most resources either oversimplify this topic (giving you a paragraph on each technique without any real guidance) or dive so deep into chemistry that you need a textile engineering degree to follow along. Neither approach helps you make actual decisions about your actual products.

This guide takes a different approach. We’re going to map out the complete landscape of fabric coloring, from dyeing methods that change the fundamental color of your fabric to printing techniques that apply patterns and graphics. We’ll cover the resist techniques (like batik and tie-dye) that blur the line between the two. And most importantly, we’ll give you a practical framework for figuring out which methods make sense for your specific situation.

If you’re already familiar with the basics and want to jump straight to a specific technique, use the section headers to navigate. We’ve built this guide as a hub that connects to deep-dive articles on each method, so you can go as shallow or as deep as you need.

Dyeing vs. Printing: The Fundamental Distinction

Before we get into specific techniques, let’s clarify the two main categories of fabric coloring, because confusing them leads to expensive mistakes.

Dyeing changes the color of the fabric itself. The dye penetrates the fibers and becomes part of the material. When you dye a white cotton shirt blue, every fiber in that shirt is now blue. Dyeing is typically used for solid colors, though techniques like tie-dye create patterns through selective dye application.

Printing applies color to the surface of fabric in specific areas to create patterns, graphics, or images. The base fabric remains its original color wherever ink or dye isn’t applied. Your screen-printed t-shirt graphic sits on top of the fabric; it doesn’t change the color of the shirt itself.

This distinction matters because it affects everything: which techniques are available to you, what the final product looks and feels like, how durable the color will be, and what it costs. A solid-color swimsuit uses dyeing (or sublimation, which we’ll get to). A t-shirt with a logo uses printing. A batik sarong uses a combination of both, which brings us to the third category.

Resist techniques occupy the territory between dyeing and printing. Methods like batik, tie-dye, and shibori use physical or chemical barriers to prevent dye from reaching certain areas of fabric, creating patterns through the dyeing process itself. These techniques produce results you simply can’t achieve with conventional printing, which is why they remain relevant even in an age of digital everything.

How Fabric Composition Determines Your Options

Here’s where things get practical. The fiber content of your fabric doesn’t just influence which coloring methods work best; it often determines which methods work at all.

Different fibers have different molecular structures, and dyes are formulated to bond with specific types of molecules. Use the wrong dye on the wrong fiber and you’ll get poor color uptake, terrible washfastness, or no color at all. This isn’t a suggestion or a best practice. It’s chemistry.

Natural cellulose fibers like cotton, linen, rayon, and viscose bond with reactive dyes. These dyes form a chemical bond with the cellulose molecules, resulting in excellent colorfastness. Most traditional dyeing and many printing techniques work beautifully on these fabrics.

Protein fibers like silk and wool require acid dyes or specific reactive dyes formulated for protein fibers. The chemistry is different, and using cotton dyes on silk will give you disappointing results.

Synthetic fibers like polyester and nylon need disperse dyes, which work under heat and pressure to penetrate the synthetic polymer structure. This is why sublimation printing (which uses heat to bond dye with polyester) works so well on performance fabrics and swimwear but fails completely on cotton.

Blends complicate everything. A 50/50 cotton-poly blend will accept some techniques partially, giving you muted colors or inconsistent results. For sublimation printing, you typically need at least 65% polyester content to get acceptable vibrancy. We cover specific fabric-technique combinations in detail in our complete fabric compatibility reference.

Dyeing Methods: When Color Happens in the Process

If you’re working with solid colors, understanding when dyeing happens in the production process helps you make smarter decisions about cost, flexibility, and quality.

Solution dyeing (also called dope dyeing) adds color to synthetic fibers before they’re even extruded into thread. The pigment is mixed into the liquid polymer, so the color is literally built into the fiber at the molecular level. This produces the most colorfast, fade-resistant fabric possible, and it’s more environmentally sustainable because it uses less water than other methods. The catch? It requires mill-level minimum orders, often tens of thousands of meters. You’ll find solution-dyed fabric in high-end performance wear and outdoor textiles where fade resistance is critical.

Yarn dyeing colors the yarn before it’s woven or knitted into fabric. This is how you get heathered effects, woven stripes, and plaids without printing. Yarn-dyed fabrics have a depth of color and texture that piece-dyed fabrics can’t match. The tradeoff is higher minimums and longer lead times compared to piece dyeing.

Piece dyeing dyes finished fabric (the “piece”) and is the most common method in the industry. It offers the most flexibility because you can manufacture fabric in greige (undyed) and dye it to specific colors as orders come in. Most of the solid-color fabric you encounter is piece-dyed.

Garment dyeing takes finished, sewn garments and dyes them as complete pieces. This creates that soft, lived-in look and feel that’s popular for casual wear. The tradeoffs include some shrinkage (which must be factored into pattern making), slight color variation between pieces, and the fact that thread and labels often dye differently than the main fabric. For certain aesthetics, these “imperfections” are features, not bugs.

For a deeper exploration of when each method makes sense, see our guide to fabric dyeing methods. If you’re specifically interested in the sustainability and chemistry aspects, our chemical vs. natural dyes comparison covers that territory.

Printing Techniques: Applying Patterns and Graphics

Printing is where most brands spend their creative energy, and the range of options can be overwhelming. Let’s break it down by the major categories.

Screen Printing

Screen printing pushes ink through a mesh stencil onto fabric, one color at a time. It’s been the industry workhorse for decades because it produces vibrant, durable prints at reasonable cost for medium to large runs. The ink sits on top of the fabric, giving screen prints a distinctive look and feel that many brands specifically want.

Screen printing comes in several forms. Hand screen printing is an artisan method where skilled printers manually pull ink across the screen. Flat-bed screen printing handles both garments (like t-shirts) and yardage. Rotary screen printing uses cylindrical screens for continuous roll production, though registration challenges limit how many colors you can layer effectively.

The economics favor larger orders because each color requires a separate screen, and screen setup costs are fixed regardless of how many pieces you print. For simple designs in large quantities, screen printing remains hard to beat. Our screen printing deep-dive covers the full spectrum from hand screens to industrial production.

Sublimation Printing

Sublimation uses heat to transform solid dye into gas, which then bonds permanently with polyester fibers at the molecular level. The result is vibrant, photorealistic prints that won’t crack, peel, or fade significantly over time. The print becomes part of the fabric rather than sitting on top of it.

There’s a critical limitation: sublimation only works on polyester and polyester-blend fabrics (typically 65%+ polyester content). It simply won’t bond with natural fibers. This makes it the dominant technique for swimwear, activewear, and performance apparel where synthetic fabrics reign, but useless for cotton t-shirts.

For brands working with swim and activewear, sublimation is often the obvious choice. It handles all-over prints beautifully, maintains color vibrancy through chlorine and salt water exposure, and moves with stretchy fabrics without cracking. We cover this in depth in our complete guide to sublimation printing.

DTG (Direct-to-Garment) Printing

DTG works like an inkjet printer for fabric. It sprays water-based ink directly onto garments, allowing for photorealistic images with unlimited colors and no setup costs per design. This makes it perfect for small runs, samples, and print-on-demand operations.

The tradeoffs? DTG works best on cotton (it struggles with synthetics), durability doesn’t quite match screen printing, and per-unit costs are higher for large orders. But for testing new designs or offering extensive customization, DTG’s flexibility is unmatched.

One thing rarely discussed: DTG and screen printing don’t just differ in process; they produce visually different results. Screen printing’s color-separated boldness has a distinct aesthetic compared to DTG’s photographic gradients. Sometimes the “right” choice is about the look you want, not just cost or convenience. Our DTG vs. screen printing comparison explores this aesthetic dimension that most guides ignore.

Digital Printing for Natural Fabrics

What if you want digital printing quality on cotton or other natural fabrics? That’s where reactive and pigment digital printing come in. Reactive printing uses dyes that bond with cellulose fibers (similar chemistry to reactive dyeing), while pigment printing applies pigments that sit on the fabric surface. Each has tradeoffs in terms of hand feel, durability, and color vibrancy. Our digital printing for natural fabrics guide helps you navigate these options.

Other Methods

Heat transfer printing, DTF (direct-to-film), and heat transfer vinyl each have their place, though we’d be honest: they’re often used where other methods would produce better results. They can be appropriate for specific applications, but fashion brands should understand the quality and durability tradeoffs before committing. We provide an honest assessment of heat transfer and DTF methods if you’re considering these options.

Resist Dyeing: Where Tradition Meets Modern Fashion

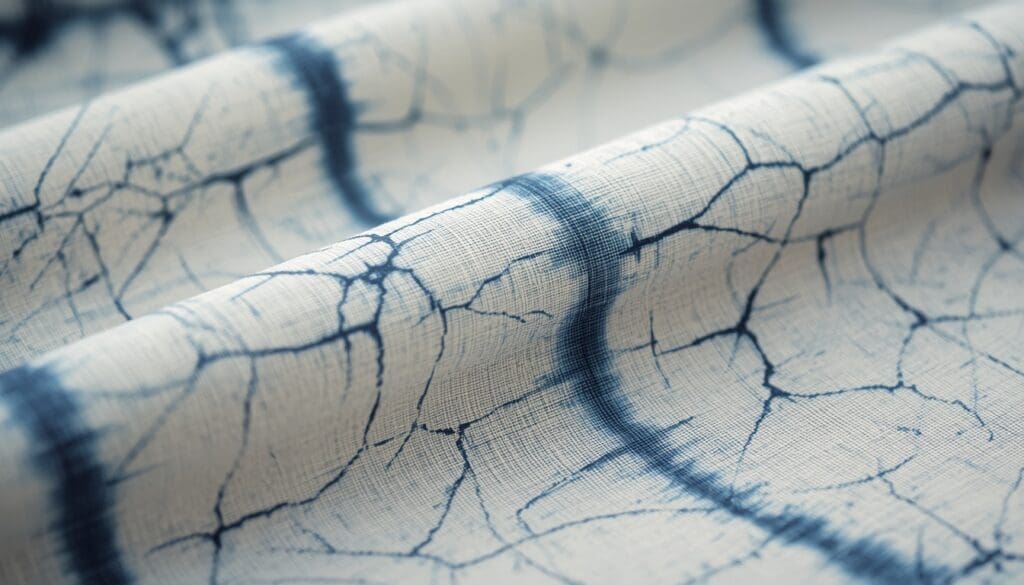

Resist techniques create patterns by preventing dye from reaching certain areas of fabric. They produce effects impossible to achieve with conventional printing, which is why these often-ancient methods remain relevant for contemporary fashion.

Batik

Batik uses wax as a resist. Hot wax is applied to fabric in patterns, the fabric is dyed, and the wax is removed to reveal undyed areas. Multiple rounds of waxing and dyeing can create complex, multicolored designs. The characteristic “crackle” effect where dye seeps through cracks in the wax is unique to batik and often prized as a mark of authenticity.

What most people don’t realize is that batik exists on a spectrum from fully artisan to production-efficient. Hand-drawn batik (batik tulis) using a canting tool represents the highest level of craftsmanship, with single pieces taking days to complete. Copper stamp batik (batik cap) offers repeatable patterns with handmade character. Screen batik applies wax through screens before dyeing, making batik aesthetics accessible at volume. Each method has its place depending on your positioning and price point.

Given our Bali manufacturing base, batik is a particular specialty for us. Our comprehensive batik guide covers all four methods and helps you determine which approach fits your brand.

Tie-Dye and Shibori

Tie-dye and its Japanese cousin shibori use binding, folding, stitching, or clamping to create resist patterns. These techniques are experiencing a fashion moment, but they’ve been practiced for centuries across cultures worldwide. From the spiral patterns of American tie-dye to the sophisticated pleating of arashi shibori, these methods produce organic, often unpredictable results that celebrate handcraft.

Production considerations matter here: true artisan tie-dye and shibori involve significant hand labor, and each piece varies. For some brands, that variation is the point. For others, it’s a challenge. Our tie-dye and shibori guide explores both the techniques and the production realities.

Hand-Painted Fabric

Sometimes the right answer is a skilled artisan with a brush. Hand-painted fabric appears in resort wear, sarongs, luxury pieces, and anywhere a brand wants to emphasize wearable art. It’s labor-intensive and difficult to scale, but for the right application, nothing else achieves the same effect. See our hand-painted fabric guide for when this makes sense.

Making the Decision: A Practical Framework

With all these options, how do you actually choose? Start by answering these questions:

What’s your fabric? Fiber content eliminates certain techniques immediately. Polyester opens up sublimation; cotton opens up DTG and reactive printing. Blends require careful evaluation. If you haven’t chosen your fabric yet, let your coloring needs influence that decision.

What kind of design do you need? Solid colors point toward dyeing methods. Simple graphics with few colors favor screen printing. Photorealistic images or complex gradients need digital methods. Artisan aesthetics suggest resist techniques.

What’s your order volume? Small runs favor DTG, sublimation, or artisan methods without setup costs. Larger runs make screen printing increasingly economical. Very large runs might justify yarn dyeing or solution dyeing for solids.

What’s your budget reality? Per-unit costs vary dramatically between methods, but so do setup costs. A technique that’s expensive per unit might be cheapest overall for small orders, and vice versa.

What aesthetic are you after? This question gets overlooked, but it matters. The bold, punchy look of screen printing differs from the soft gradients of DTG. The organic variations of batik differ from the precision of digital printing. Sometimes the “right” technique is the one that looks right for your brand, regardless of other factors.

What durability do you need? Swimwear demands chlorine resistance. Workwear needs to survive industrial washing. Fashion pieces may prioritize aesthetics over longevity. Match the technique to the product’s life.

If you want help working through these decisions, our Fabric Coloring Advisor tool can recommend techniques based on your specific project parameters.

Production Realities

A few practical notes that affect real-world decisions:

Roll printing vs. garment printing matters more than people realize. Printing fabric on the roll (before cutting and sewing) enables all-over prints and better production efficiency at scale. Printing finished garments limits where you can print (seams and construction get in the way) but allows for smaller quantities and quicker turnaround. Know which approach your manufacturer uses and how it affects your options.

MOQs vary wildly. DTG can print a single piece. Screen printing typically wants 50-100+ per design. Sublimation falls somewhere in between. Piece dyeing might require 300+ meters. Yarn dyeing often starts at 1,000+ meters. Understanding minimum orders helps you match techniques to your business stage.

Lead times differ. Digital printing methods turn around fast. Screen printing needs time for screen preparation. Artisan techniques take as long as they take. Build realistic timelines based on your chosen methods.

Sampling matters. Whatever technique you choose, sample before committing to production. Colors look different on screen than on fabric. Hand feel varies. Durability needs testing. The investment in proper sampling prevents expensive surprises.

Where to Go From Here

This guide gives you the map; the deep-dive articles give you the territory. Based on what you’re trying to accomplish, here’s where to go next:

Working with swimwear or activewear? Start with our sublimation printing guide.

Printing t-shirts or casual apparel? Our screen printing article and DTG vs. screen printing comparison will help you choose.

Interested in batik, tie-dye, or artisan techniques? Our guides to batik, tie-dye and shibori, and hand-painted fabric cover these in depth.

Need to understand solid color options? See our dyeing methods guide and chemical vs. natural dyes comparison.

Want to know what works on your specific fabric? Our fabric compatibility reference provides the complete matrix.

Not sure where to start? Try our Fabric Coloring Advisor for personalized recommendations based on your project.

And as always, if you have questions about a specific project, we’re here to help. This stuff is genuinely complicated, and sometimes a conversation is worth more than a hundred articles.