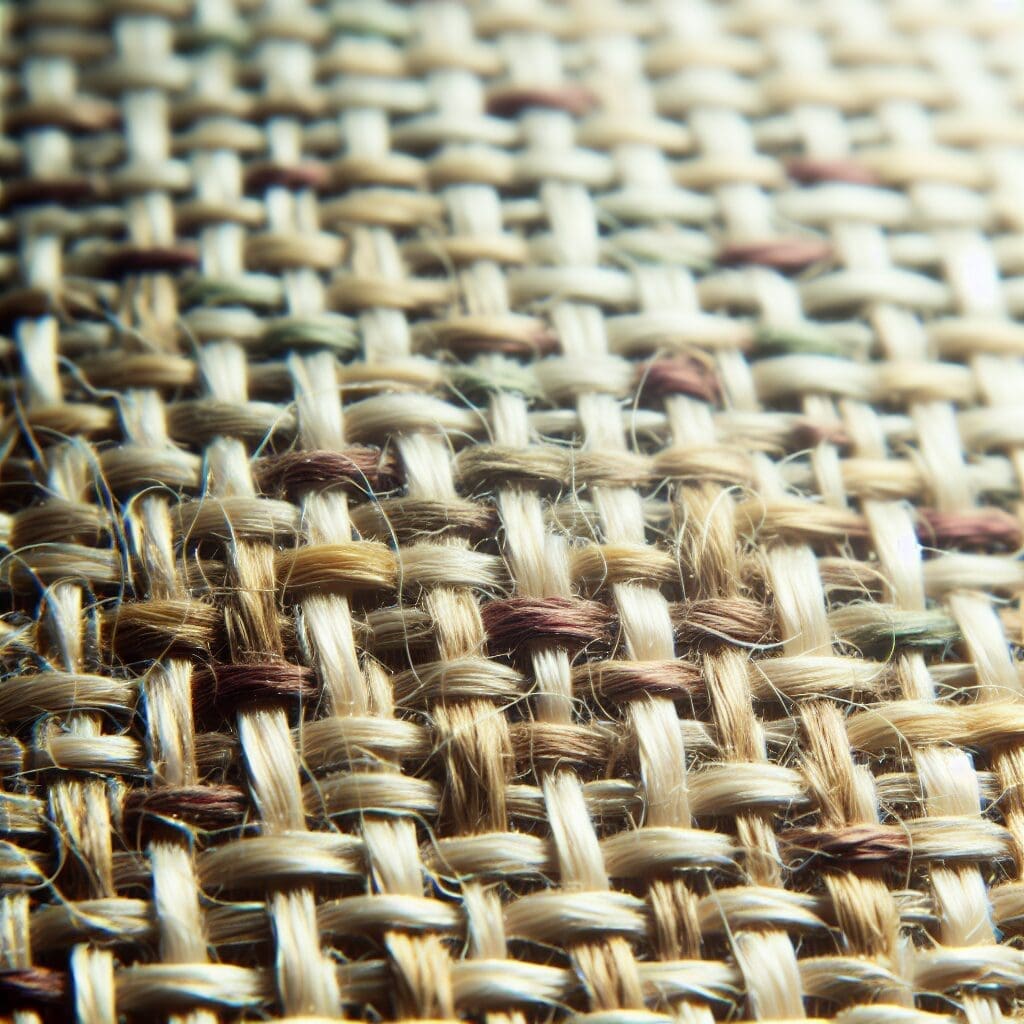

In a world increasingly driven by sustainability and eco-conscious choices, hemp fabric shines as a powerhouse material that combines centuries-old tradition with cutting-edge innovation. Whether you’re a fashion designer seeking sustainable textiles or a manufacturer aiming to reduce environmental impact, understanding hemp fabric’s multifaceted nature is essential. This comprehensive guide dives deep into the origins, history, properties, applications, and future trends of hemp fabric, equipping you with the knowledge to make informed decisions and champion this versatile material.

Section 1: Origin and Source

Comprehensive Overview of Hemp Fabric

Hemp fabric is derived from the fibers of the Cannabis sativa plant, specifically cultivated for industrial purposes. Unlike its psychoactive cousin, marijuana, industrial hemp contains minimal THC (<0.3%), making it legal and safe for textile production in many countries. The plant’s stalks are the primary source of fiber, which is extracted through a process called retting — a natural breakdown of the plant’s outer layers.

Hemp’s cultivation dates back over 10,000 years, with archaeological evidence suggesting its use in ancient China, Egypt, and Central Asia. Today, major hemp-producing countries include China, Canada, France, and the United States, each leveraging their unique climates and agricultural practices to optimize fiber quality.

Raw Materials and Sourcing

Hemp fibers come from the plant’s stalks, which can reach heights of 4-5 meters. The fibers are extracted from the inner woody core (bast fibers) and outer fibers, each with different characteristics. The bast fibers are long, strong, and flexible, making them ideal for textiles. Modern sustainable farming practices emphasize organic cultivation, crop rotation, and minimal pesticide use, aligning hemp farming with environmental stewardship. Are you curious about how hemp cultivation impacts soil health? It actually improves soil quality by phytoremediation — absorbing heavy metals and pollutants!

Section 2: Extensive History

Invention and Early Use

Hemp’s history as a textile dates back to prehistoric times. Ancient civilizations like Mesopotamians and Chinese used hemp for clothing, ropes, and paper. In fact, some of the earliest known textiles were made from hemp fibers, showcasing its durability and versatility. The Chinese, for instance, cultivated hemp as early as 4,000 BCE, integrating it into their daily life for clothing, sails, and even medicine.

Historical Significance

During the Middle Ages, hemp was a critical resource across Europe, used extensively for shipbuilding — notably in the British Navy, where hemp ropes and sails were indispensable. The famous Declaration of Independence was drafted on hemp paper, emphasizing its longstanding importance. The plant’s role in industrial revolution advancements—such as the invention of the cotton gin—further cemented its influence.

Evolution of Production Methods

Initially, hemp processing relied heavily on manual retting and hand-spinning techniques. The advent of mechanized retting and decortication in the 19th and 20th centuries increased efficiency. Today, innovations like enzyme retting — which uses microbial enzymes to break down plant tissues — reduce water usage and environmental impact. This evolution reflects a shift towards sustainable, eco-friendly production practices.

Cultural Impact

Throughout history, hemp has been both celebrated and stigmatized, often due to its association with psychoactive cannabis. However, modern legal reforms are redefining its image, positioning hemp as a sustainable crop for textiles, bioplastics, and more. The cultural renaissance around hemp underscores its potential to contribute positively to global environmental goals.

What lessons can we learn from hemp’s rich history to inform future textile innovations? Clearly, resilience and versatility are key themes that continue to resonate.

Section 3: Physical Properties and Composition

Physical Characteristics

Hemp fibers are known for their exceptional strength—approximately 1.5 times stronger than cotton—making them highly durable. They possess a natural luster and a slightly coarse texture that softens with use and washing. The fibers are naturally resistant to UV rays, mold, and pests, which enhances longevity.

Hemp fabric exhibits excellent breathability and moisture-wicking properties, keeping the wearer cool and dry. Its high tensile strength contributes to its use in heavy-duty applications, while its ability to retain shape is advantageous for structured garments.

Chemical Composition

The primary chemical components of hemp fibers include cellulose (~70%), hemicellulose, lignin (~10-15%), pectin, and waxes. The high cellulose content is responsible for its strength and flexibility. The lignin provides rigidity and resistance to decay. This composition allows for diverse processing techniques, including spinning, weaving, and chemical treatments.

Performance Attributes

- High tensile strength

- UV resistance

- Antimicrobial properties

- Biodegradability

- Low water requirements for cultivation

Are there misconceptions about hemp’s durability? Not at all — it’s one of the toughest natural fibers available, capable of withstanding harsh environmental conditions.

Section 4: Applications Across Industries

Fashion and Apparel

Hemp fabric is making waves in sustainable fashion, featured in collections by brands like Patagonia and Stella McCartney. Its breathable and antimicrobial qualities appeal to eco-conscious consumers. Designers incorporate hemp for casual wear, activewear, and even luxury garments due to its unique texture and environmental benefits.

Home Furnishings

From curtains and upholstery to rugs and bedding, hemp’s durability and natural aesthetic make it ideal for interior design. Its resistance to pests and mold ensures longevity in various environments.

Industrial Uses

Hemp’s strength lends itself to applications such as biodegradable plastics, composite panels, and insulation materials. The automotive industry is exploring hemp-based composites for lightweight vehicle parts, reducing reliance on fossil fuels.

Niche Applications

In cosmetics, hemp seed oil is prized for its nourishing properties. In the medical field, hemp-derived products are gaining traction for their therapeutic benefits. Is there a sector where hemp could disrupt traditional materials? The possibilities are expanding daily.

Section 5: Comparative Analysis

Hemp vs. Cotton

- Strength: Hemp is approximately 1.5x stronger than cotton.

- Environmental Impact: Hemp requires less water and pesticides.

- Durability: Hemp fibers are more resistant to wear and tear.

Hemp vs. Linen

- Texture: Hemp tends to be coarser initially, softening over time, while linen (flax) is smoother from the start.

- Strength: Both are strong, but hemp surpasses linen in tensile strength.

- Eco-friendliness: Both are eco-friendly, but hemp’s faster growth cycle offers advantages.

Unique Characteristics

Unlike synthetics, hemp is biodegradable and has a minimal carbon footprint, making it highly attractive for sustainable fashion. Its resistance to pests and UV rays also reduces chemical use, aligning with eco-conscious manufacturing principles.

Section 6: Environmental Impact and Sustainability

Production Footprint

Hemp’s rapid growth (up to 4 meters in 100 days) and minimal water requirements significantly lower its environmental impact. It naturally suppresses weeds, reducing herbicide use. Processing hemp into textiles consumes less energy compared to synthetic fibers.

Recyclability and Eco-friendly Alternatives

Hemp fibers are 100% biodegradable, decomposing within 6 months under proper conditions. Researchers are developing hemp-based bioplastics and composites as sustainable alternatives to plastics. Certification standards like OEKO-TEX and GOTS ensure environmentally friendly cultivation and processing.

Challenges and Opportunities

Despite its benefits, hemp’s adoption faces regulatory hurdles in some regions. However, ongoing legal reforms and technological advancements promise to accelerate its integration into mainstream fashion and industry.

Section 7: Care and Maintenance

Washing Instructions

- Wash in cold water to preserve fiber integrity.

- Use mild detergents to prevent fiber degradation.

- Avoid bleach, which can weaken fibers.

Storage Recommendations

- Store in a cool, dry place away from direct sunlight.

- Ensure the fabric is clean and completely dry before storage to prevent mold.

Longevity Tips

- Limit exposure to excessive sunlight to prevent discoloration.

- Gentle laundering and proper storage extend fabric life.

Section 8: Future Trends and Innovations

Emerging Technologies

Innovations like enzyme retting and bio-based chemical treatments are reducing water and energy consumption. Researchers are exploring nanotechnology to enhance hemp fabric’s properties, such as stain resistance and UV protection.

Market Trends

The global hemp textile market is projected to grow at a CAGR of 12% over the next five years, driven by consumer demand for sustainable fashion. Major brands are increasingly incorporating hemp into their eco-friendly lines.

Potential New Applications

Advances in processing could enable hemp to replace synthetic textiles in sportswear, outdoor gear, and even high-performance technical fabrics, aligning with the trend toward versatile, eco-conscious materials.

Section 9: Conclusion

Hemp fabric stands out as a resilient, sustainable, and versatile material with a rich history and promising future. Its unique combination of strength, eco-friendliness, and adaptability makes it an excellent choice for innovative fashion and industrial applications alike. As the industry shifts toward greener practices, hemp’s role is set to expand, offering designers and manufacturers a powerful tool to meet evolving consumer expectations and environmental standards.

Are you ready to incorporate hemp into your next collection? Dive into the potential of this extraordinary fabric and help shape a more sustainable future for fashion.